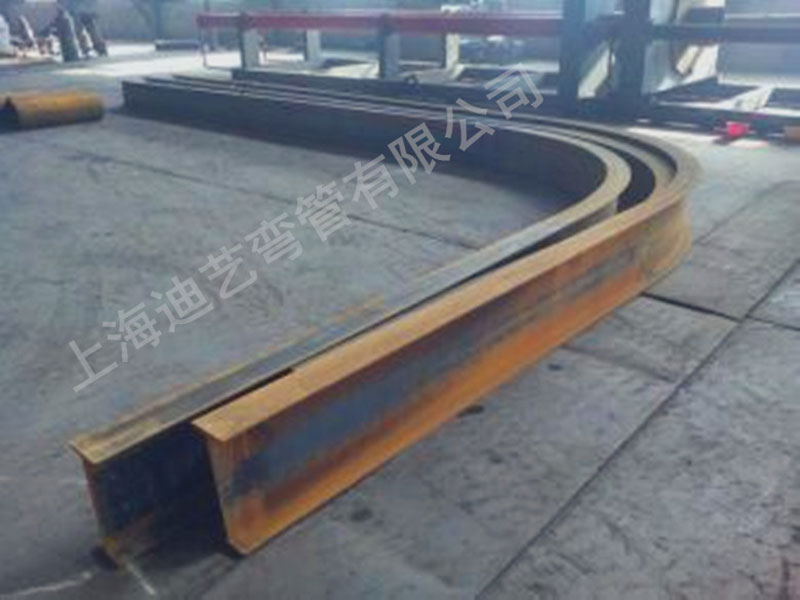

Medium frequency bending pipe

Medium frequency pipe bending is currently widely used in pipeline prefabrication in engineering fields such as electric power, petroleum, chemical industry, navigation, and nuclear industry.

The medium frequency pipe bending machine uses medium frequency electric induction heating to bend the workpiece under local heating conditions. Compared with the general cold pipe bending machine, it not only does not require a complete set of special molds, but the machine tool volume is only 1/3 to 1/2 of the cold pipe bending machine of the same specification. The medium frequency hot pipe bending process is a more economical and effective one among the various existing pipe bending processes.

The process of medium frequency pipe bending is to put an induction coil on the part of the steel pipe to be bent, clamp the pipe head with a mechanical rotating arm, and pass a medium frequency current through the induction coil to heat the steel pipe. When the temperature of the steel pipe rises to a plastic state, a mechanical thrust is used at the rear end of the steel pipe to push it forward and bend it. The bent steel pipe part is quickly cooled with a coolant. In this way, the pipe is continuously bent while heating, pushing, bending and cooling.

This process can avoid the uneven wall thickness of the pipe bend caused by the thinning of the convex edge of the pipe wall by tension and the thickening of the concave edge of the pipe wall by pressure during the forming of the traditional pipe bending process. This process can be used to produce 180° elbows with small radius (R≈D) and thin wall (t/D≈0.015) with uniform wall thickness, which cannot be achieved by other pipe bending processes. If the various process parameters are designed reasonably, this process can ensure that the wall thickness of each part of the pipe remains unchanged during the pipe bending process, that is, it is always equal to the wall thickness of the straight pipe blank before deformation. This process can be used to produce pipes with multiple bending angles such as 45°, 90°, 180°, etc. of the same caliber on the same bull horn mandrel at one time, with high production efficiency.